Rossini are the world leaders and pioneers for Rubber Rollers, Sleeves, and Mandrels for

the printing and flexible packaging converting industry. Rossini Spa of Italy

headquartered in Milan established in 1928 and having grown over the years due to

innovation and quality today have factories in L'Aquila(Italy), Atlanta(USA),

Barcelona(Spain), Sao Paulo(Brazil) and a new factory inTimisoara (Romania) .They also

have sales offices in Shenzen(China), UK, France, Germany thus offering support to

customers worldwide.

Rossini are the original suppliers to leading CI Flexo machine manufacturers like F&K (Bobst Group), W&H, Uteco, Flexotecnica,

Comexi etc. including Indian manufactures such as Uflex Engineering, Manugraph India Ltd, EChaar,

Equipment's Pvt Ltd, Perfect Printgraph Engineers LLP, Polygraph Printing

technologies ltd etc. With the growing demand for flexo Rossini are

constantly innovating new products. During Drupa 08 Rossini launched the new Click Clack

with special protection ring with register slot instead of the conventional metal slot

on their newly developed Starcoat sleeves for wide web flexo presses. The Starcoat

sleeves ensures very high mechanical strength and dimensional stability and comes with a

3year guarantee from Rossini.

Rossini has recently introduced the new High Modulus Carrier without core compressible

layer that provides the ability to print at the highest quality at over 700m/min

engineered and proven to dampen harmonic resonance and reduce dynamic print-deck

vibration. The carrier sleeve is air-mounted resulting in significantly easier on press

use by operator, and improved safety.

Photoflex Sleeve

A sleeve with a special antistatic polymer conforming to safety standards issued by the "PTB" (Physikalisch-Technischen Bundesanstalt – Germany). Perfectly ground and lapped for flood-coating applications.

Anilox Sleeve

Designed for ceramic plasma coating and laser-engraving by any anilox

manufacturer.

A fiberglass sleeve with core expansion layer is clad in aluminium for uniform

dispersion of heat that is built up during the ceramic plasma coating process.

A very pure aluminium alloy is used to minimize oxidation that can cause

blistering of the ceramic coating.

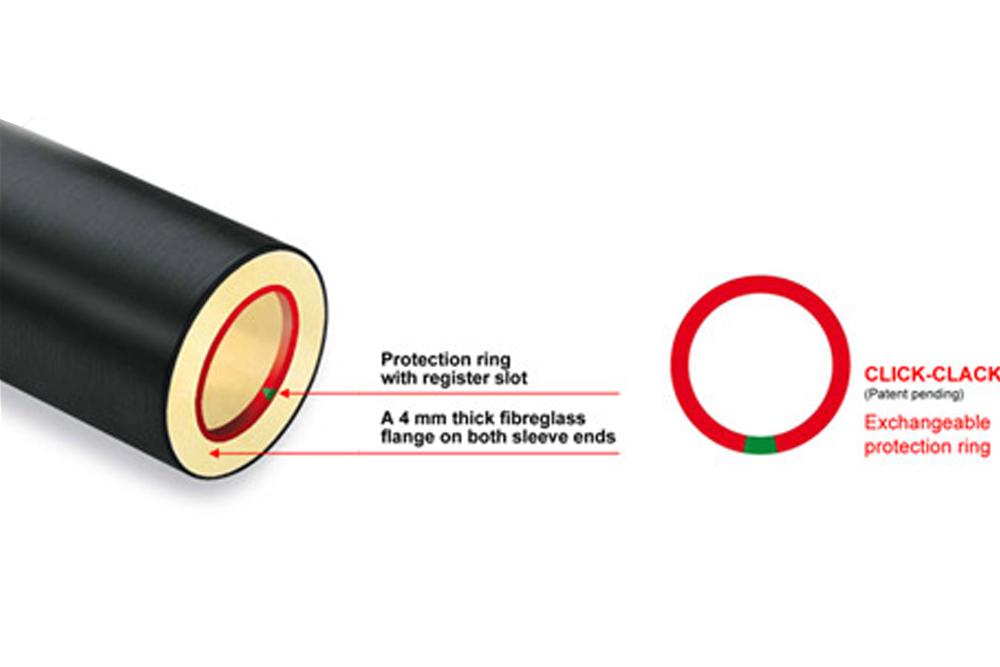

Everglass Sleeve

A superior sleeve engineered to provide extended dimensional stability.

The fibreglass reinforces surface and provides very high mechanical strength.

100% resistant to all solvents.

Recommended for 4-colour printing and for extremely subtle subjects. This sleeve

prints multiple images with up to 60 lines per cm.

Technical Data

The following data refers to an air mandrel with a max. T.I.R. of 0.005 mm:

• Max. T.I.R. 0,02mm

• Max. diameter change over 3 years 0,02 mm

(working temperature 18 ÷ 40 °C)

• Total encapsulation – no absorption of solvent or moisture

• Patent pending quick-change protection ring with register slot

• Not affected by humidity

• Hardness - 75 Shore D

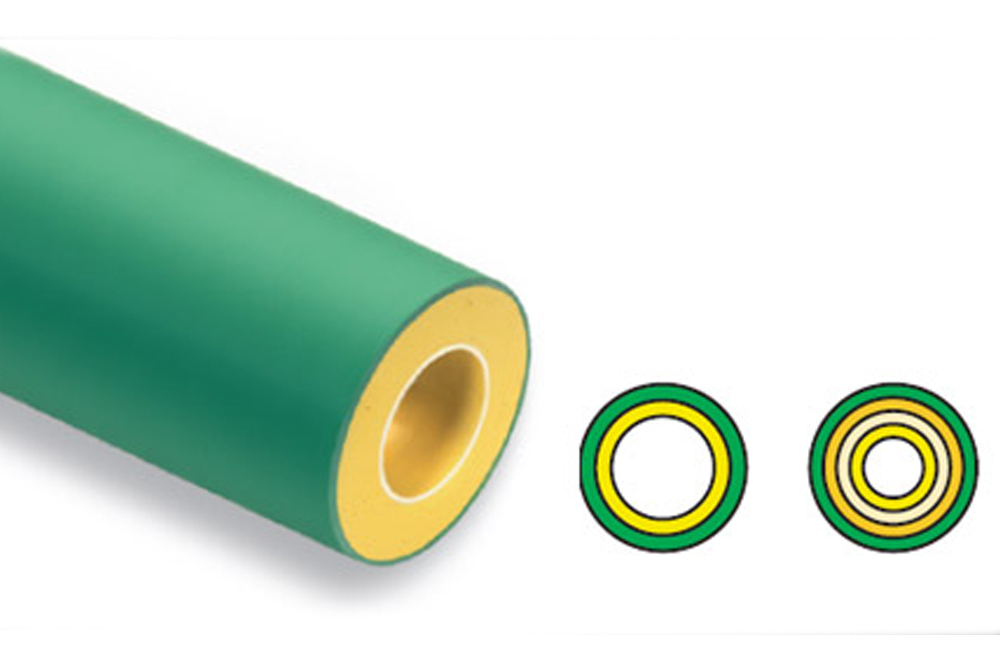

Evergreen Sleeve

A fiberglass sleeve coated in layers of ultra-light polyurethane with wall thickness from 2 to 70 mm.

Everstat Sleeve

In conformity to the work safety standards issued by the "PTB"

(Physikalisch-Technischen Bundesanstalt – Germany)

for flexographic presses, these sleeves are made of anti-static

polyurethane with wall thickness from 5 to 70 mm. The static load is discharged

by means of carbon fibre, for resistivity of less than 1 MΩ.

Carrier Sleeve

Carrier sleeves are specially designed and engineered to provide extremely tight

tolerances.

Carbon fibre is utilized to obtain the required tensile strengths, diameter and

TIR tolerances.

Carrier sleeves are adapters that reduce sleeve thickness and price whilst

improving print quality.

Thin, Evergreen, Everglass, Photoflex, and Everstat sleeves can be mounted

on all Carrier styles.

Carrier disponibili:

Flow-Thru Carrier:

Utilizes a single mandrel air source for mounting both Carrier and plate sleeve.

Standard Carrier:

Uses a secondary air source for mounting plate sleeves via an internal piping

system.

Used on presses with independent air supply system.

High Modulus Carrier:

Engineered to damper and reduce print-deck vibration on wide-web, high speed

presses.

Custom-made Carriers:

can be produced to the specifications of all OEM press manufacturers.

Carbobridge Sleeve

High Modulus Carbon-Fibre bridge sleeve without a core compressible layer that

provides

the ability to print at the highest quality at over 700 m/min. Engineered and

proven to damper

harmonic resonance and reduce dynamic print-deck vibration. The bridge is

air-mounted,

resulting in significantly easier on-press use by the operator – improved safety

with less

potential for injury.

Available Carbobridge Types:

Flow-Thru CarboBridge:

Utilizes a single mandrel air source for mounting both bridge and plate sleeve.

The most common style for current press designs.

Standard CarboBridge:

Uses a secondary air source for mounting plate sleeve via an internal piping

system.

Used on presses with independent rear air supply system as well as

mounter/proofers

Custom CarboBridge:

All CarboBridges can be produced to the specifications of any OEM press

manufacturer.Quality control of Carrier sleeves – illustrating tube deflection

test and laser

measurement of finished diameter.

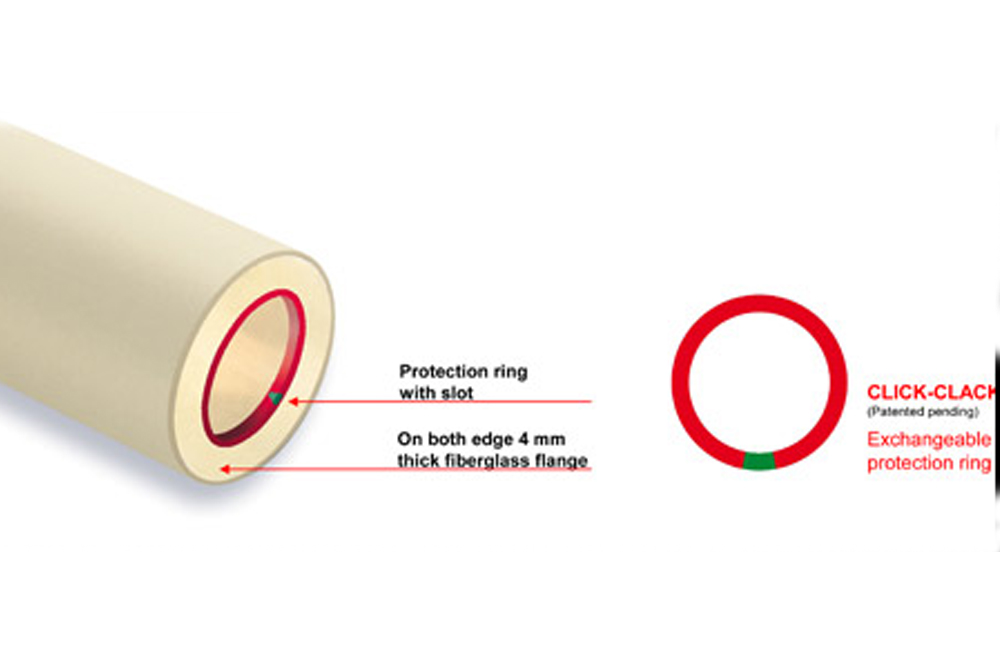

Starcoat Sleeve

A superior sleeve, created to provide total dimensional stability

The conductive surface is applied to a fibreglass reinforced layer. This dual

construction

ensures very high mechanical strength and constant dimensional tolerance over

time.

Highly resistant to solvents.

Recommended for 4-colour printing and for extremely subtle highlights and

vignettes.

This sleeve, with 3-year warranty, prints multiple images. It is made of

conductive materials

conforming to work safety standards issued by the "PTB" (Physikalische

Technische

Bundesanstalt – Germania) for flexographic presses.

Technical Data :

The following data refers to an air mandrel with a max. T.I.R. of 0.005 mm:

• Max. T.I.R. 0,02mm

• Max. diameter change over 3 years 0,02 mm

(working temperature 18 ÷ 40 °C)

• Static dispersion < 1 Mega Ohm

• Total encapsulation – no absorption of solvent or moisture

• Patent pending quick-change protection ring with register slot

• Not affected by humidity

• Hardness - 75 Shore D

Bieffebi based in Bologna ,Italy and established in 1955,is specialised and dedicated

for manufacturing of new generation Plate Mounters for the flexographic

printing/converting industry. .With indepth expertise and many a patents, their

innovative technology is considered amongst the best in the world and having presence in

over 90 countries. Bieffebi offers plate mounting solutions to both ,Wide- & Narrow Web

flexo and also offers dedicated solution for Corrugating industry

Quality and Precision is the mission of this company, beginning with fine attention to

detail in designing to the highest international standards with respect to accuracy ,

reliability and repeatability. This has enabled Bieffebi to grow and establish

themselves as a world leader in an even more competitive market.. Thanks to Bieffebi's

flexibility, leading edge technology and many Patents to its credit . Bieffebi has

recently added three important world Patents for their mounting systems:

Pressure roller to remove the air bubbles between sticky back and sleeve; Virtual Data

Processing (called VDP) which enables the proof without inks; Automatic Quality, Control

System (AQCS) through Laser which allows the checking of the geometric tolerances

(Patent Pending) of the printable areas and of all the equipment. Our success with UNICA

343 model for wide web flexo is unparelled. .They have recently introduced UNICA 323

dedicated for the narrow web flexo which has also met with tremendous response and

continue to be pioneers offering solutions for the corrugating industry.

Their success and growth has been due to the fact that they specialise and dedicated

only to the manufacture of Plate mounting machines thus in apposition to develop and

offer the latest technology to our valued customers world over. Over a 1000 installation worldwide including 35 installations

in India.

FLEXIBLE PACKAGING

UNICA 343 VM

Machines for mounting flexo plates on cylinders and/ or sleeves for printing

presses in plastic film and paper industries with both motorized cameras and

axis as well as VIS software {Virtual Information system- Patent}

For repeats from mm 240 upto 1250

The machines is complete with- * 2 sony motorized zoom colour cameras each one

provided with a ring of led lights which features an adjustable luminous

intensity for a constant operation quality. Automatic focus with possibility of

manual adjustment. * 2 LCD touch screen colour monitors,* Industrial PC, * VIS

software which enables for the automatic detection of the references (Microdots

or crosses) by means of motorized cameras and digital storage of mounting jobs.

This software uses files in 1:1 real scale and allows for the digital control of

the mounting job in register without the need of a proof on paper with inks, *

Internet Remote assistance

Traho 426

Machine to detach plate and tape from sleeves and to apply tape on sleeves

For repeats from 240 up to 1250

Designed and manufactured to facilitate the operator during the dismounting

phase after printing.

It allows to remove the plate from the sleeves without using the hands avoiding

thus any damages, while to remove easily the tape it is enough to hold it up to

prevent gluing.

The sleeve is put on three supporting rollers. One idle and motorized to get the

detachment of the plate or of the tape.

The detach speed is according to EC Regulation. The operator has to his disposal

a bidirectional Pedal.

A container is placed under the roller to receive plates of any sizes.

CORRUGATED

Mounting and proofing machine for corrugated board sector for mounting flexo

plates on sleeves; with Image Mounting System (Bieffebi patent) which allows to

mount in perfect register plates carrying dots, crosses and also no reference at

all.

Machines are provided with:

Operator interface consisting of a PC with a 15" monitor, mouse, keyboard and

pre-installed modem for remote assistance Automatic plotter able to draw any

combination of mounting/layout lines, as entered , or previously stored

OMNIA338 is provided with proofability in real scale

1:1 and round mounting with final result as the job has been flat mounted

(Bieffebi patent).

Planus 348

Flat mounting machine of flexo plates on mylar for the corrugated board industry

The highest quality and precise Bieffebi Planus 348 allows the flat mounting

of the flexographic plates on mylar. At the end of the machine, it generates an

automatic quality report for the control of the register. Different types of

mounting are performed by the Bieffebi Planus 348 on the references or on the

flexo plate Graphic File with the PATENTED VDP SYSTEM (Virtual Data Processing)

patents EP1666251 (B1) – US8037819 (B2). It enables also to mount flexo plates

of small dimensions for the parts job.

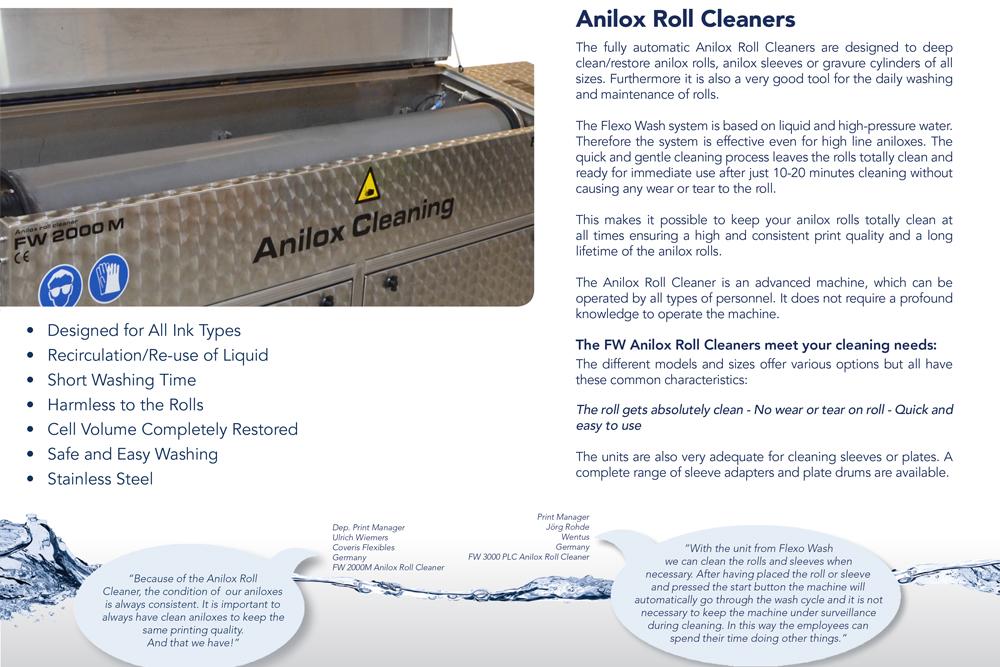

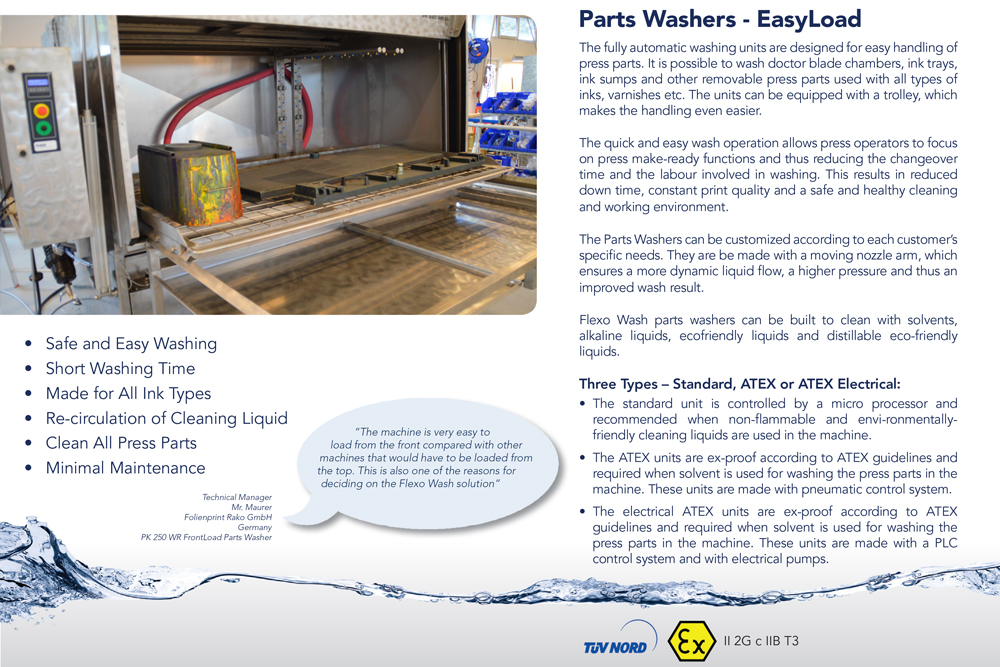

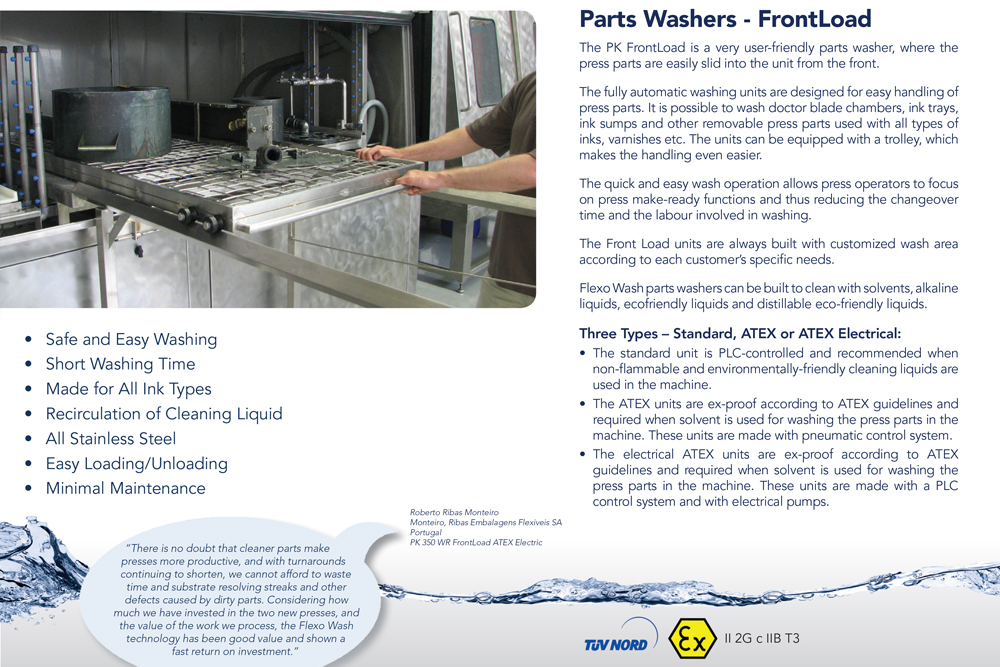

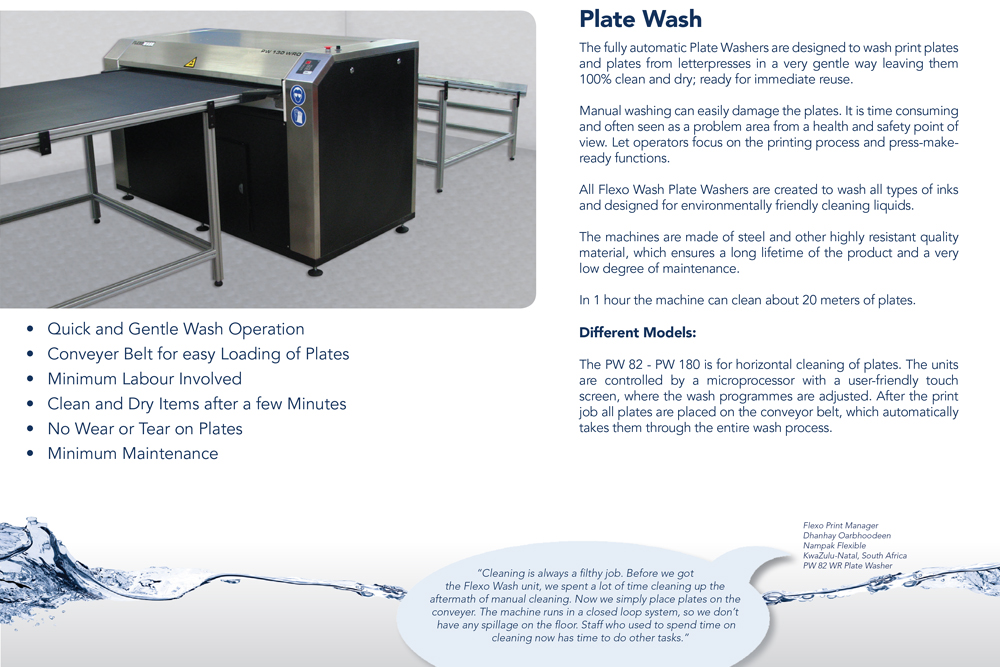

Flexo Wash was founded in 1990 by an inventive Danish label printer who faced the increased requirements for improved print quality as well as a safe and efficient production.Flexo-Wash has been in this line for over 2 decades with its HQ in Denmark and offices in U.K, France, USA, and Malasyia. Through constant Innovation and development today Flexo Wash is the world's leader in flexographic and convertor cleaning equipments. Flexo-Wash has been re-defining Annilox Roll cleaning and Flexo Plate cleaning from day one using eco-friendly cleaning liquids which are re-circulated in all FlexoWash units.It is the only system that offer's Cleaning, Rinsing and Drying in one machine. FlexoWash offers complete automatic system thus avoids the risk of damage to the rolls and plate due to manual handling. Traditional methods of cleaning by pads, abrasive cleaners and brushes are loosing their effectiveness in deep or small cells as they are unable to penetrate the cell depth effectively Today everyone knows that the aniloxes/Plates need to be clean to get an optimal printing quality. Properly cleaned anilox rolls/ Plates also reduce set up time, reduce press downtime, minimize waste of ink and substrate, improve productivity and increases the roll / plates life. Many a times a printer is not able to obtain the same desired result for a repeat job this may happen due to improper cleaning of anilox/platesof which he Is not sure of. Therefore a proper and efficient cleaning of anilox rolls/Plates is must . Because of the finer lines it is also a must to find a safe, gentle and automatic cleaning method, that will cause no wear or tear on the delicate aniloxes/ plates. With the growing needs of cleaning press parts FlexoWash have introduced various models depending upon customer requirement to clean from 1 to 4 sets of press parts in a single wash. The parts washer offered can clean the parts with eco friendly liquids as well as solvents depnding upon the customer requirement.

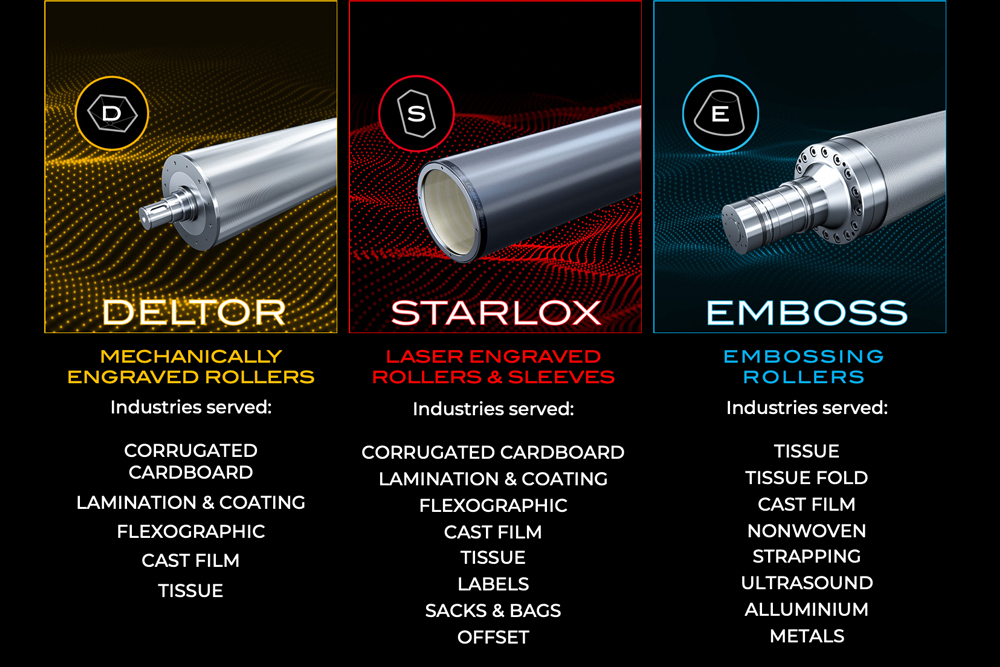

Simec Group is a private company, still managed by its founder who has been supported

for years by the second generation, operating in the flexo & embossing sector since

1960. Today Simec is one of the most representative companies in the international

market. During the past years, Simec registered several patents and developed many

specific equipment and production systems. Simec production program, besides covering

all industry sectors connected with printing and resin/glue coating, also includes

embossing rolls for several industries, particularly focusing on the paper industry of

non-woven, plastic materials and aluminium.

The wide experience gained in several application fields and the constant collaboration

throughout the years with machine manufacturers and printers from all branches where

Anilox rollers are used convinced us that for the full satisfaction of our customers we

had to offer them even better products than ever in the past.

For more info on Mechanically Engraved rolls, Laser engraved rolls & Embossing rolls

please visit their website www.simecgroup.com